Plastic injection molding

When the design of a product is completed, the project moves to the industrialization stage. During this step, the manufacturing tooling are designed and manufactured, including those for plastic parts. These are the injection molds.

The development of injection molds follows three main steps:

- Plastic part design analysis and material selection.

- Manufacturing and testing of injection molds.

- First parts qualifications (validation before mass production).

The different kind of injection mold processes are:

- Single or multi-cavity mold.

- Overmolded mold.

- Bi-injection mold.

With a few hundred molds developed, TXCube performs all the steps described on behalf of its customers.

Part design analysis and raw material selection

The main issues met in plastic injection molding come very often from the design of the parts. When designing products, TXCube applies the design guidelines of the plastics industry in order to have a successful industrialization.

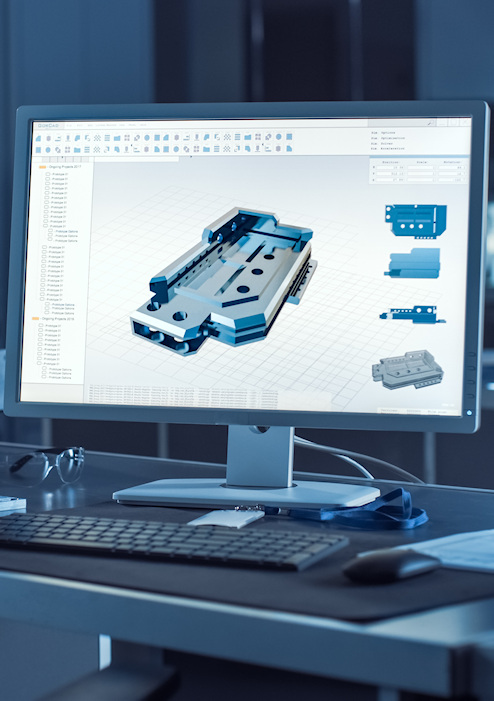

The DFM (Design for Manufacturing) carried out before the study of injection molds allows to confirm that the rules of the plastics industry are well applied (draft angles, position of injection points, sliders, hot runners, etc.). TXCube also carries out rheological studies on the parts before the manufacturing of the tooling to guarantee the correct flow of the selected plastic in the injection mold.

The choice of plastic raw materials is also as important as the design of the part. TXCube currently processes many different thermoplastics (PC, ABS, PMMA, PA6, TPE, etc.). We provide guidance to our customers in the choice of raw materials.

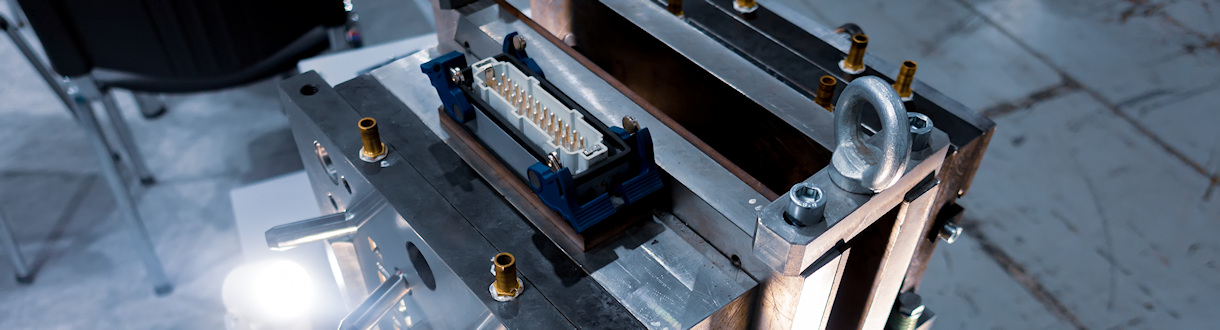

Injection molds manufacturing and testing

After the DFM step and the choice of raw material, we launch the manufacturing of the tooling. We anticipated the number of cavities, the positions of the injection points, etc. TXCube relies on molding service companies and plastic injection molding companies for this complex phase. TXCube teams is always on the manufacturing site for the first tests of the injection molds.

In these steps, we analyze the parts and possible patches to be applied on the tools. This analysis is done according to 3 main axes:

- Cosmetic Analysis.

- Dimensional analysis.

- Assembly improvement.

At each stage, a test report is carried out. If necessary, this report allows a further modification of the tooling.

Qualification of plastic injection parts

Once all the plastic injection molds have been modified and qualified to be used, TXCube then qualifies the parts and the tooling. The product / process couple is then approved and mass production can start.

This qualification is based on first samples and includes all the elements to know about the part:

- Part technical data (3D, 2D drawings, material data sheet, specifications).

- Critical dimensions control reports (FAI: First Article Inspection report where all dimensions and capabilities are reported).

- Mold technical data (3D, drawings, maintenance plan, etc.).

- Quality data (inspection sheet of molded parts, process monitoring plan, etc.).

The first sample files and the golden sample parts are signed jointly by TXCube and the customer to start mass production.

An important point: the mold belongs to our customer.

Got a project ?

TXCube brings the experience on the best way to meet your challenges. So, don’t wait and